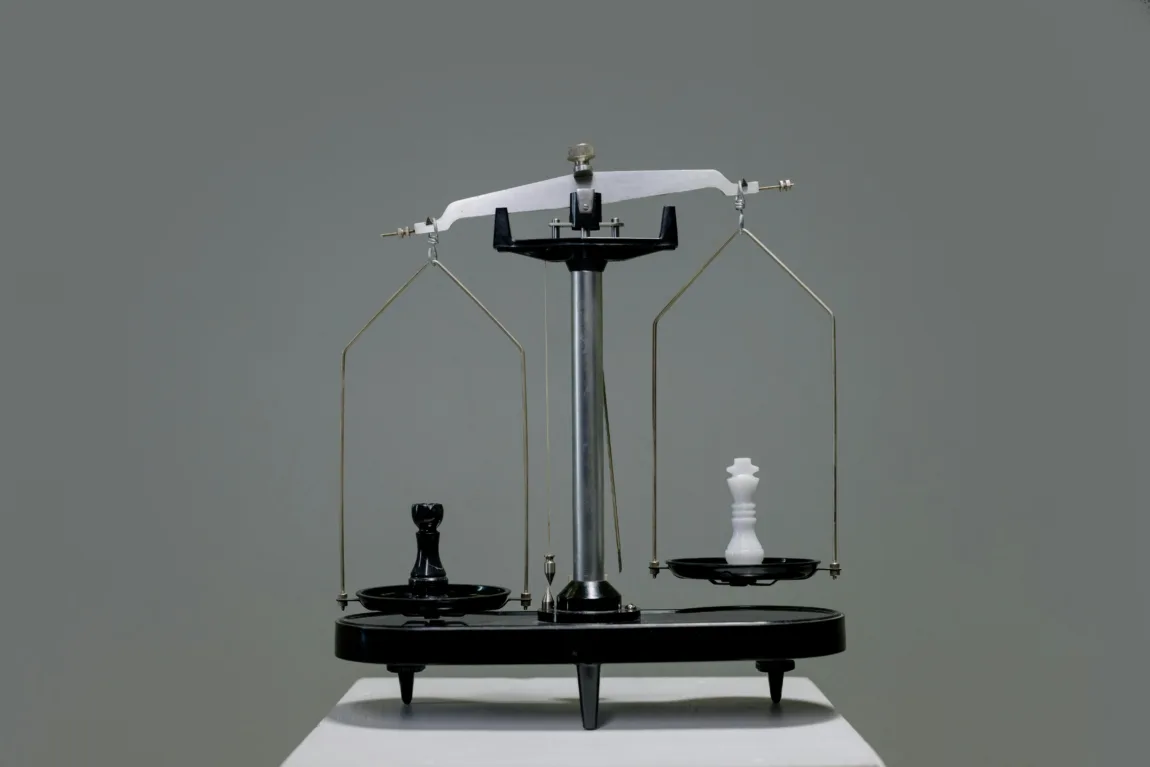

Balancing a budget and finding the right cost reduction strategies requires both an eye for detail and commitment to the company’s mission. On one side, there’s the pressure to fuel the company’s ambitions—secure the best materials, negotiate favorable contracts, and foster strategic supplier relationships. On the other side, executives demand leaner operations, higher margins, and rapid procurement cost savings to keep the business competitive.

Every procurement leader knows the paradox: how do you spend to save? Procurement teams are often caught in an internal struggle as well and are fighting perceptions within their own organizations. For some stakeholders, procurement is often seen as a “cost center” rather than a strategic partner.

It’s a battle between quick wins and long-term strategy—between cutting corners today or building sustainable, scalable partnerships for tomorrow. The stakes go even deeper on a personal level.

How do you balance the immediate need for procurement cost reduction without jeopardizing your career by making decisions that may hurt quality, timelines, or supplier trust down the road? It’s tough.

But here’s the good news. Cost reduction doesn’t have to come at the expense of value or efficiency. The right cost reduction strategies in procurement can empower procurement leaders to maximize both. How do you turn challenges into opportunities for innovation and savings? What processes and tools—like AI contract review software—can help procurement manage these competing priorities? Let’s find out.

1. Analyze and optimize procurement spend

Data doesn’t lie—it leads. Intuition is no longer enough. Procurement decisions based purely on “gut feel” may have worked in the past, but now they’re a risky gamble. The difference between controlling costs and watching them spiral out of control often comes down to how well you understand your spend data.

That’s where procurement cost savings truly begin—with spend analysis.

Imagine having full visibility into every dollar spent across categories, suppliers, and departments. Without this insight, it’s easy for inefficiencies to slip through the cracks. Are you unknowingly paying multiple suppliers for similar goods? Are certain teams negotiating their own contracts, bypassing corporate agreements with better terms? When left uncovered, these blind spots can quietly inflate procurement costs.

Procurement leaders can connect the dots, uncover patterns, and eliminate redundancies. Data-driven insights allow procurement teams to segment their spend by supplier, product, and geography. This segmentation helps prioritize opportunities for improvement, or renegotiating contracts for discounts.

If you go even further, conducting regular supplier audits ensures that you’re getting the value promised. Audits reveal compliance gaps, hidden fees, and performance issues that could erode savings. Meanwhile, spend categorization—grouping similar goods—makes it easier to benchmark costs and negotiate better deals.

Once you’ve identified inefficiencies, what do you do with that information? It’s time for strategy #2.

2. Consolidate suppliers

Multiple suppliers may give you options, but they can also inflate costs and add layers of inefficiency. Think of it this way: the more suppliers you have, the harder it becomes to maintain control over pricing, terms, and performance. Supplier consolidation offers a powerful solution by turning quantity into quality.

If you work with fewer strategic partners, procurement teams gain stronger leverage in negotiations. Consolidating spend with key suppliers often results in volume discounts, better payment terms, and preferential treatment. Suppliers are more inclined to go the extra mile—offering faster lead times, value-added services, and customized solutions—when they know they’re a top priority.

So, how do you identify consolidation opportunities? Spend analysis, as mentioned earlier, is your guide.

You can pinpoint areas where multiple suppliers provide similar goods or services. E.g., are you buying office supplies from five different vendors across regions when consolidating to one could secure a national discount? Are two different teams unknowingly sourcing the same materials from separate suppliers? Procurement data reveals these hidden inefficiencies and opens the door for supplier rationalization.

However, consolidation doesn’t mean putting all your eggs in one basket. You still need contingency plans to avoid disruptions if a supplier underperforms or faces a crisis. A strategic approach involves consolidating a manageable number of core suppliers, supplemented by a few alternates.

3. Leverage long-term supplier contracts

Locking in long-term contracts can be invaluable for procurement cost savings.

Think about it—predictability in pricing allows your organization to

- Plan more accurately,

- Avoid market volatility, and

- Secure favorable terms

that would otherwise be up for renegotiation every six months.

Otherwise, renegotiations would last forever. Suppliers benefit as well. With the assurance of long-term business, they can offer better deals, knowing that the relationship is built for sustainability.

Long-term agreements often include fixed pricing, volume discounts, or even cost-reduction incentives tied to performance metrics. When working collaboratively with suppliers, you can negotiate contracts that prioritize both stability and mutual growth.

However, managing these agreements manually is a recipe for errors and missed opportunities. Contract renewal deadlines can slip by unnoticed, resulting in an increase in compliance risks and leaving you to catch up on important milestones that could affect costs.

Here’s how AI contract review software can help you take this administrative burden off your team.

This kind of tool automatically flags key contract dates, tracks performance clauses, and ensures compliance with negotiated terms. AI contract review software can also help identify renegotiation triggers—like changes in material costs or supplier performance—so you can seize opportunities to optimize agreements.

4. Conduct regular supplier performance reviews

Inspect what you expect, as cost reduction doesn’t stop with long-term supplier contracts. Let’s talk about how supplier performance reviews can keep those contracts—and suppliers—performing at their peak.

Contracts may set the foundation, but consistent performance is what builds true value. Suppliers often start strong when deals are inked, but over time, service levels can slip. Without ongoing evaluation, those gradual declines go unnoticed—until they hit your bottom line. This is why regular supplier performance reviews are essential to effective cost-reduction strategies in procurement.

Think of these reviews as a reality check. Are suppliers delivering on agreed timelines and quality standards? Are they meeting performance metrics outlined in the contract?

When gaps appear, you’re not just stuck with higher costs—you have leverage. A performance review is an opportunity to engage suppliers in transparent discussions about improvements and renegotiations.

For instance, if a supplier consistently underperforms, you may request cost concessions, service upgrades, or penalty clauses. Alternatively, high-performing suppliers may be rewarded with additional business or favorable terms, strengthening the partnership.

This is all about collaboration. Suppliers benefit from feedback too, as regular check-ins help identify bottlenecks on both sides of the relationship. Many procurement teams use performance management tools to automate data collection reporting to make the process even smoother. Paired with AI contract review software, you can make sure that supplier obligations and performance metrics remain in sync.

5. Implement demand management

When procurement costs start creeping up, it’s tempting to look outward and blame things like suppliers, market conditions, or price volatility. But sometimes, the real culprit is internal, i.e., unmanaged or inflated demand. Without a firm grip on what’s being requested, when, and why, procurement teams are at risk. They can over-order, stockpile unnecessary inventory, or rush last-minute purchases at premium prices.

This is why effective demand management can put procurement back in control by aligning needs with strategy.

Excess inventory ties up capital, takes up storage space, and increases the risk of obsolescence or spoilage. On the flip side, stockouts may result in expedited purchases.

You want the sweet spot—just enough inventory to meet operational needs without overburdening resources. Implementing reorder point systems and maintaining accurate inventory records helps procurement avoid these extremes.

Focus on forecasting accuracy

Plenty of organizations fall into a reactive cycle, where procurement is constantly scrambling to meet fluctuating demands. This chaos drives up costs through rushed orders and lost negotiation opportunities.

Procurement can develop more reliable demand forecasts based on historical data, seasonal trends, and project pipelines. Advanced tools can even integrate predictive analytics to anticipate shifts in demand before they occur. Control the flow, control the costs.

Procurement can also influence demand by encouraging cost-conscious purchasing. For example, setting thresholds for purchase approvals or offering budget transparency may curb over-ordering. Educating internal stakeholders on the impact of excess demand fosters a culture of mindful spending.

Demand management may not seem as exciting as negotiating a contract, but it’s a hidden powerhouse for cost control. When done right, it stabilizes procurement workflows, reduces waste, and opens the door to savings. After all, controlling what you buy is just as important as negotiating how much you pay.

By entering your email, you agree to our Terms & Conditions and Privacy Policy.